Storage, Transportation, and Installation

Robot Packaging

To ensure the structural integrity and core component safety of the humanoid robot during transportation and storage, the following packaging steps must be strictly followed:

1. Posture Adjustment

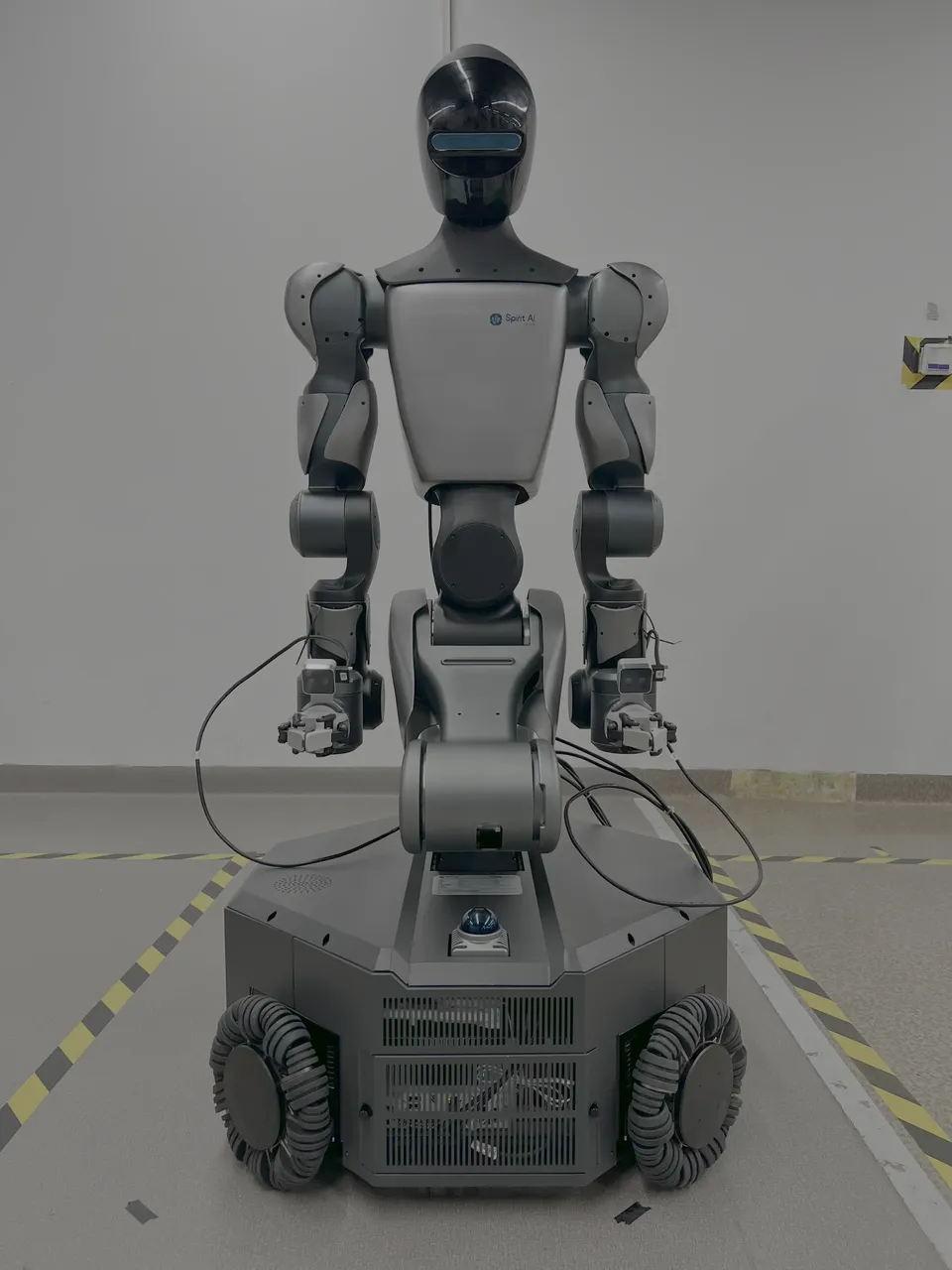

Before packing, the robot must be adjusted to the pre-packing posture (as shown in the figure below) to avoid internal component compression or loose connections due to incorrect posture.

2. Loading into the Packaging Box

Step 1

Put the robot in a protective bag, operate the robot to drive into the packaging box (during driving, align the robot with the foam cavity inside the box to prevent the armor plates or shell from scraping against the foam), and ensure that the four wheel hubs of the robot's mobile platform are aligned and evenly distributed at the bottom of the packaging box.

Step 2

Confirm that all external sensors (such as cameras, infrared modules) are in protective covers or in their original protected state;

Step 3

Place the leg padding blocks, operate the robot to squat down to the shipping posture;

Step 4

Use the built-in tensioning straps in the packaging box to secure the two wheel sets near the door side and tighten;

Step 5

Install the back support foam and waist U-shaped support foam;

Step 6

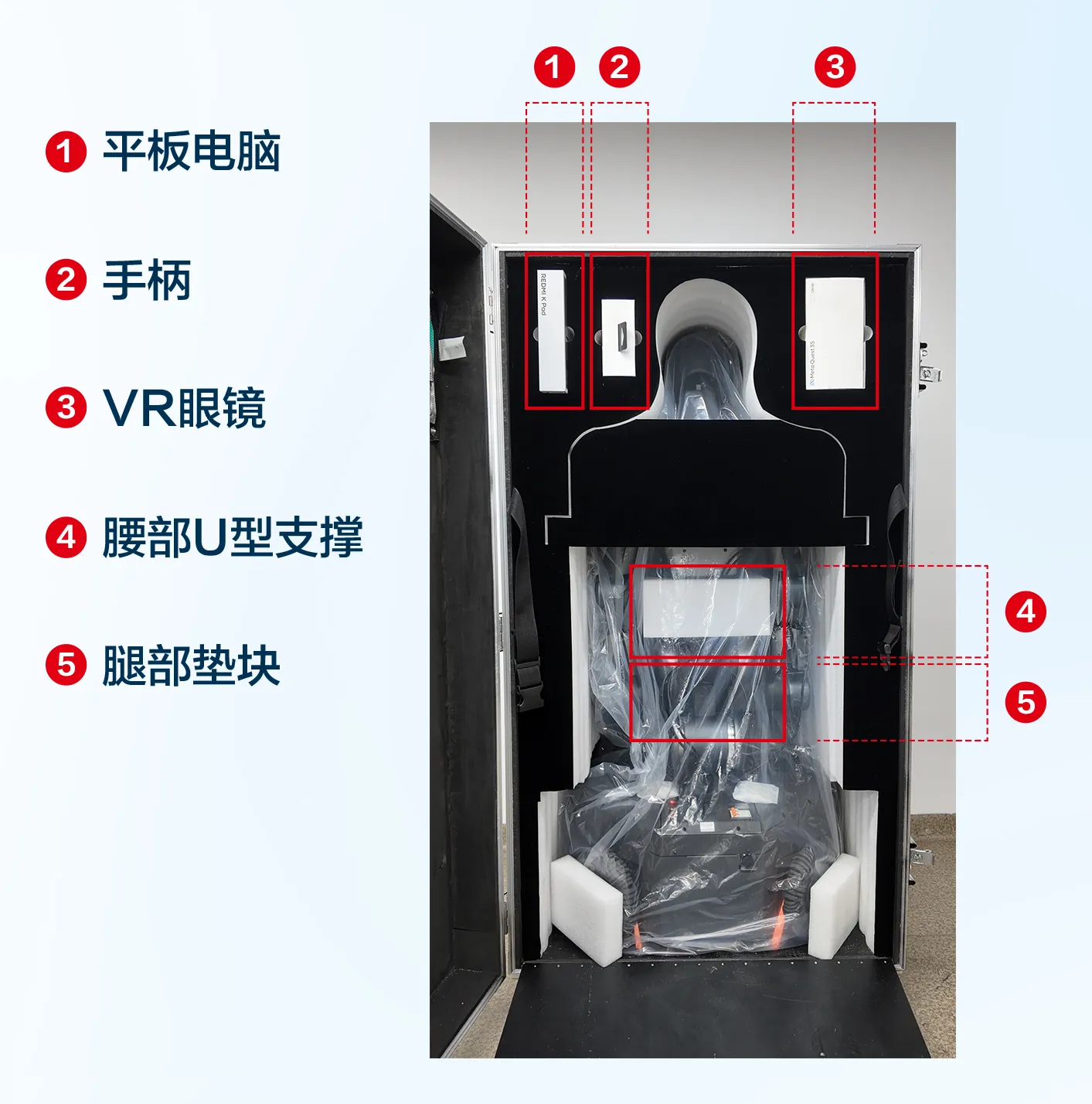

Place the accompanying accessories (VR headset, controller, tablet, etc.) in the designated storage locations;

Step 7

Fold the ramp and secure with straps;

Step 8

Close the box door and lock;

3. Sealing and Inspection

- Check that the sealing strips on all sides of the packaging box are firmly sealed to avoid internal loosening due to external impact during transportation;

DANGER

Safety Warning: It is strictly prohibited to place the robot tilted, inverted, or in any non-designated posture in the packaging box, otherwise it may cause damage to joints or core electronic systems.

Handling the Packaging Box

To ensure the safety of the robot during handling, handlers must strictly comply with the following regulations:

Handling Principles:

- Direction and Orientation

- The robot packaging box must be kept upright, with the top of the box facing up and the bottom facing down;

- The front of the box should be parallel to the ground, and must not be inverted or placed on its side;

- Compliance with Handling Labels

- When handling, be sure to read the labels on the outside of the packaging box:

- 🔹 "Handle with Care" — Violent shaking, impact, or dragging is strictly prohibited during handling;

- 🔹 "Do Not Step On or Bump" — Stepping on, squeezing, or placing heavy objects on the packaging box is prohibited;

- 🔹 "No Rough Loading/Unloading" — Using forklifts, hoisting equipment, or rough handling methods is strictly prohibited, especially on narrow or uneven surfaces.

- Brake Locking and Securing

- When handling, use non-slip handling straps or fixed brackets to prevent the packaging box from sliding or tipping during transportation;

- Throughout the transportation process, the packaging box should remain completely stationary, without shaking, swaying, or tilting.

Robot Packing Angles

LeftArm: Left ArmLegWaist: Leg-WaistRightArm: Right Arm

- Pre-packing Posture

LeftArm: [-9, -50, -20, -90, -35, 8, -7]

LegWaist: [0, 60, -90, 30, 0, 0]

RightArm: [9, -50, 20, 90, 35, 8, 7]- Shipping Posture

LeftArm: [0, 0, 0, 0, -90, -90, 0]

LegWaist: [0, 87.2376, -144.783, 58.366, 0, 0]

RightArm: [0, 0, 0, 0, 90, -90, 0]