Mechanical Structure

Mechanical Requirements

Working Environment

This humanoid robot is designed for standard industrial and service scenarios. Its working environment parameters are as follows:

Working Temperature: -10°C ~ 50°C

Operating in extremely low temperatures (below -10°C) or high temperatures (above 50°C) may cause poor joint lubrication, reduced battery performance, or material aging. It is recommended to pause operation and check equipment status when the temperature exceeds ±5°C of the range.

Working Humidity: ≤75% RH (non-condensing)

- High humidity environments (>75% RH) may cause electronic components to become damp, sensor failure, or internal short circuits. It is recommended to use moisture-proof sealed covers or environmental control devices (such as dehumidifiers) in high humidity environments.

IP Protection Rating: IP40

Special Notes:

- The robot should not operate in rainy, snowy, or outdoor environments, especially when humidity >80% and there is rain.

- If the environmental humidity is consistently above 60%, it is recommended to perform internal drying and moisture-proof maintenance every 30 days.

- The robot body and joint areas should avoid direct contact with water or corrosive liquids.

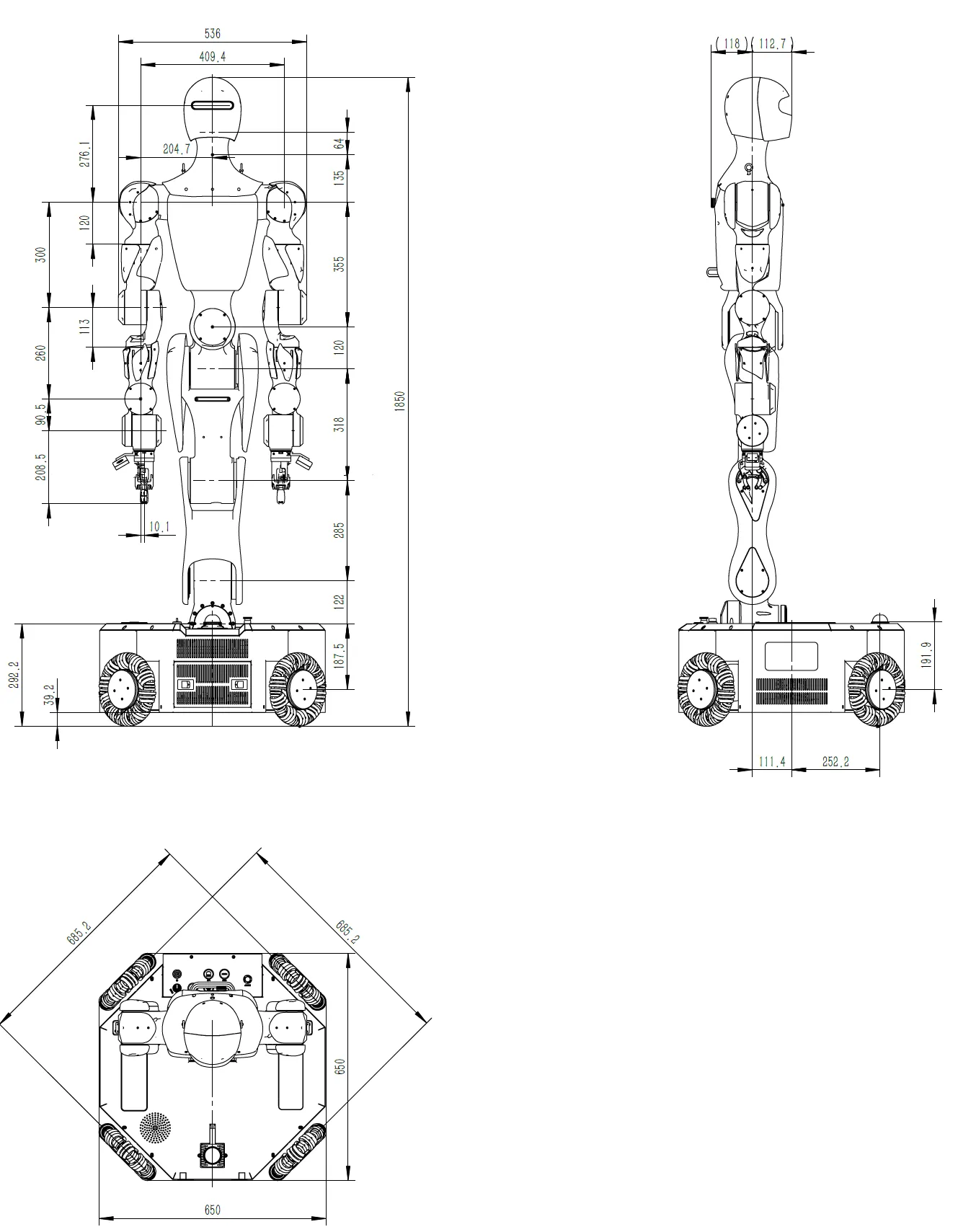

Overall Dimensions

The overall dimensions are shown in the figure below:

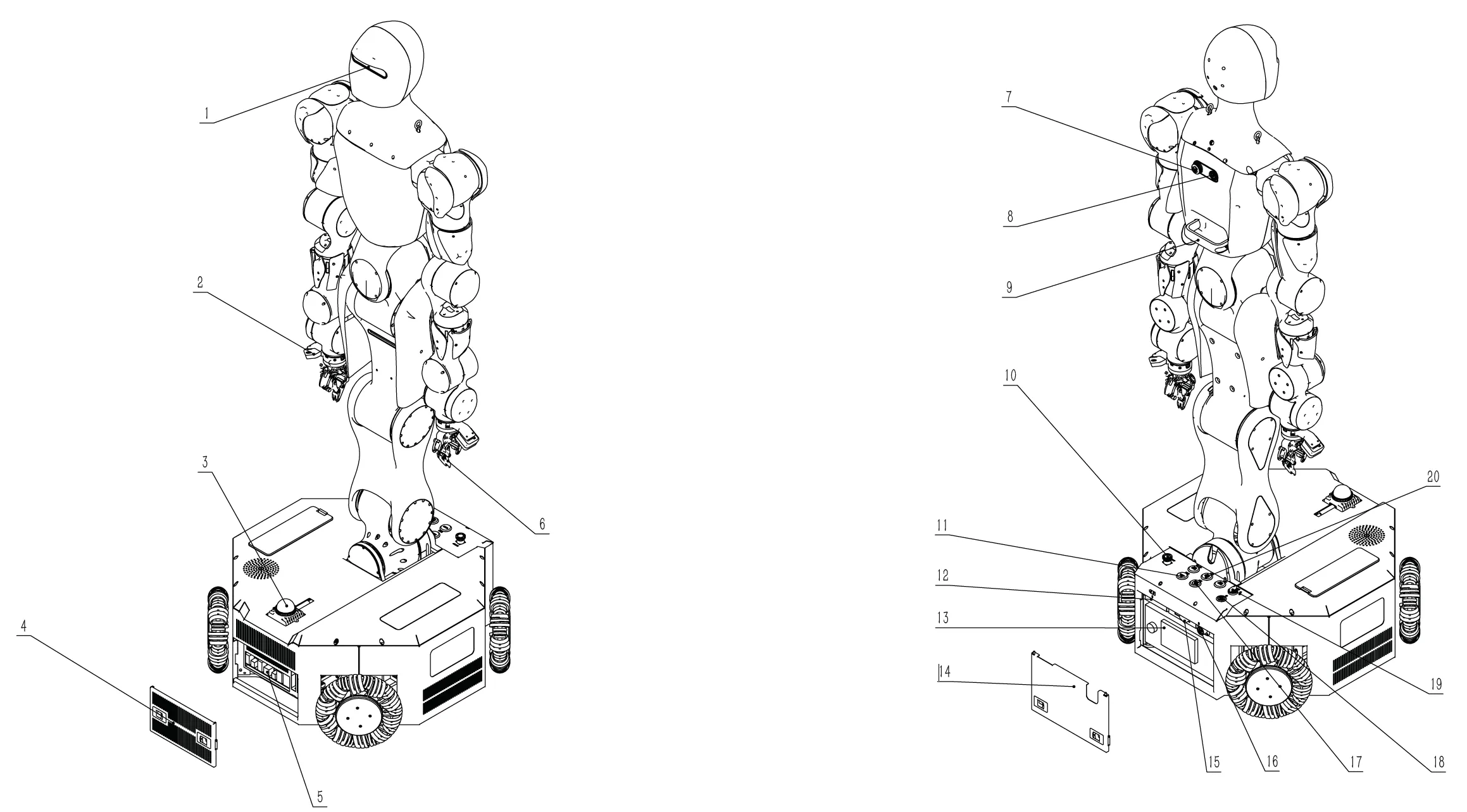

Main Components Diagram

The Moz1 robot has various sensors, actuators, interfaces, etc., as shown in the figure below:

| Component No. | Component Name | Quantity | Description |

|---|---|---|---|

| 1 | Head Camera (Intel D455) | 1 | For head perception |

| 2 | Wrist Camera (Intel D405) | 2 | For wrist perception |

| 3 | LiDAR (MID-360) | 1 | SLAM |

| 4 | Host Cover | 1 | For inference host interface maintenance |

| 5 | Inference Host Interface | 1 x USB 3.2 Gen 2x2 port(s)(1 x USB Type-C(®)) 1 x USB 3.2 Gen 2 port(s) (1 x Type-A) 3x USB 3.2 Gen 1 port(s) (2 x Type-A, 1 x USB Type-C(®)) 4 x USB 2.0 port(s) (4 x Type-A) 1 x HDMI(®) port 1 x DisplayPort 1 x Intel(®) 2.5Gb Ethernet | Head camera and wrist camera connection |

| 6 | Two-Finger Gripper | 2 | End effector |

| 7 | Back Emergency Stop Button | 1 | For stopping all robot motion in emergency situations |

| 8 | Brake Release Button | 1 | Unlock the robot for manual dragging |

| 9 | Handle | 1 | For dragging the robot |

| 10 | Mobile Platform Emergency Stop Button | 1 | For stopping all robot motion in emergency situations |

| 11 | Host Power Button | 1 | For host startup, shutdown, and forced shutdown |

| 11 | Host Power Button | 1 | For host startup, shutdown, and forced shutdown |

| 11 | HDMI Interface | 1 | For connecting external displays |

| 12 | Battery Power Interface | 1 | Lithium battery power interface |

| 13 | Lithium Battery | 1 | For powering the entire robot |

| 14 | Battery Cover | 1 | For securing the lithium battery |

| 15 | Circuit Breaker | 1 | For switching the main power on/off |

| 16 | Charging Interface Aviation Plug | 1 | Charger connection interface |

| 17 | LAN | 1 | For network communication |

| 18 | Power Button | 1 | For startup, shutdown, status indication, etc. |

| 19 | Rotary Switch | 1 | For end effector CAN and RS485 bus conversion |

| 20 | USB2.0 | 3 | For connecting external devices such as VR, mouse, keyboard, etc. |

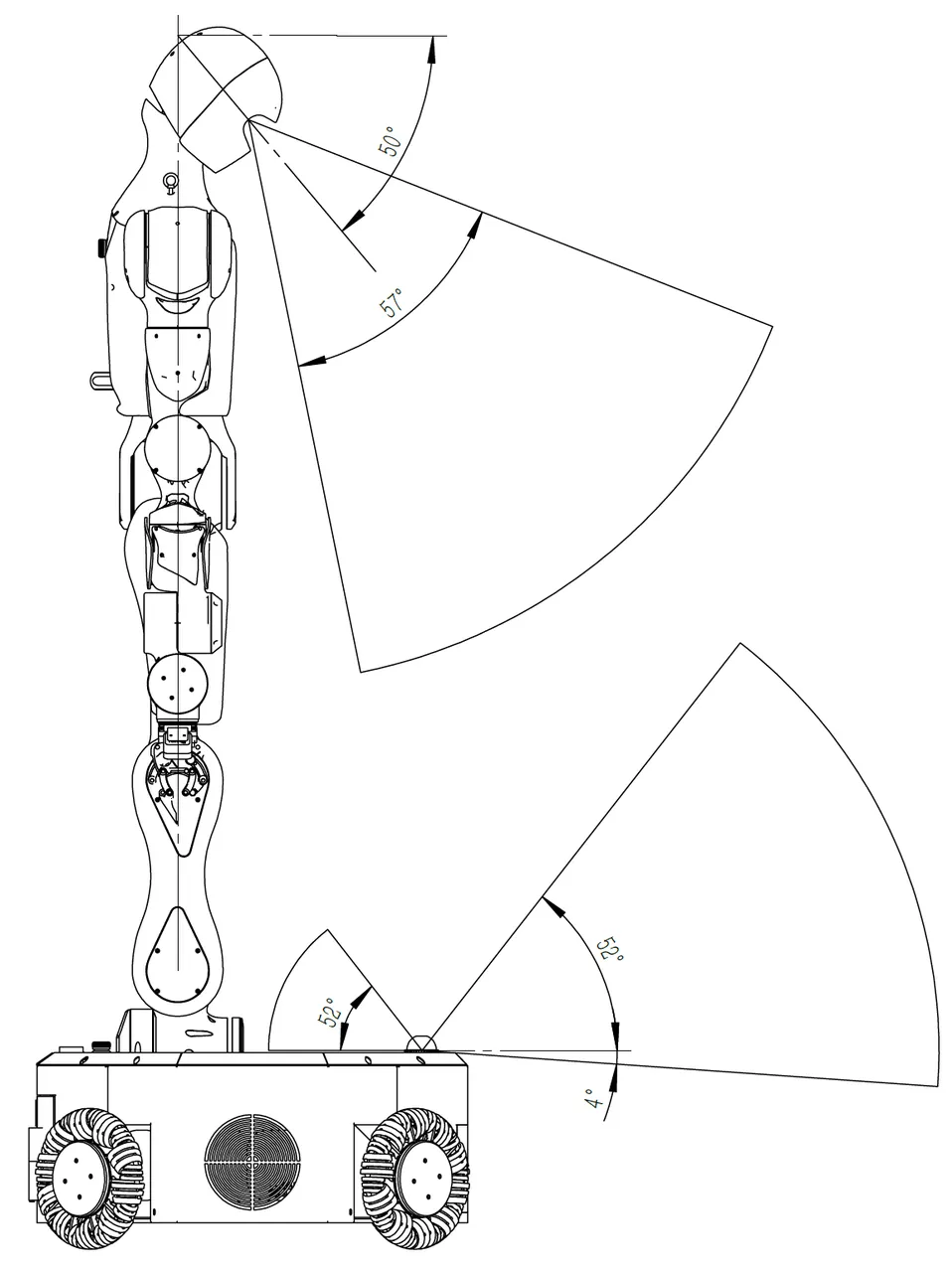

Head Camera and LiDAR Field of View

The Moz1 head camera default angle with the horizontal direction is 50°, and the field of view range is shown in the figure below. To adjust the head camera angle, refer to the head angle adjustment section. The LiDAR is placed horizontally on the mobile platform, and the field of view range is shown in the figure below.

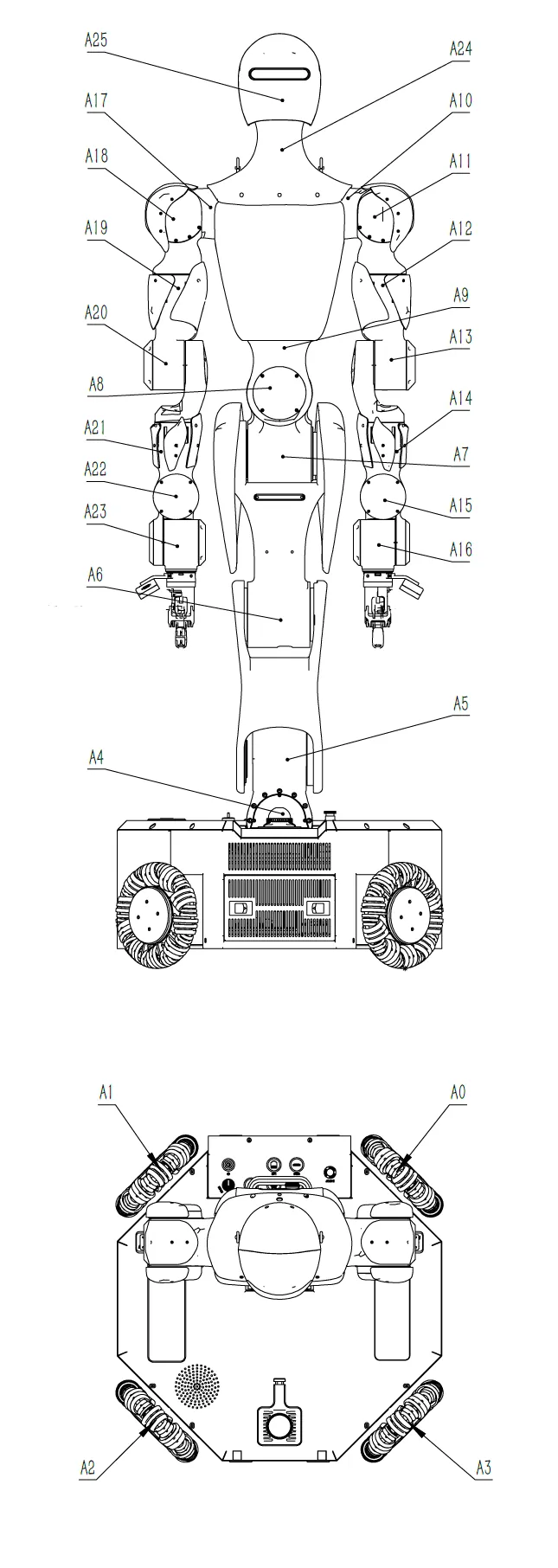

Working Range and Speed

The Moz1 axis numbers, motion range, and speed limits are as follows:

| MU Name | Joint No. | Name | Joint Limit (Deg) min | Joint Limit (Deg) max | Speed Limit (Deg/s) | Cartesian Speed vel(mm/s) | Cartesian Speed rot(deg/s) |

|---|---|---|---|---|---|---|---|

| Base | A0 | Base-0 | -inf | inf | 205 | 500 | 60 |

| Base | A1 | Base-1 | -inf | inf | 205 | ||

| Base | A2 | Base-2 | -inf | inf | 205 | ||

| Base | A3 | Base-3 | -inf | inf | 205 | ||

| LegWaist | A4 | LegWaist-0 | -30 | 30 | 65 | ||

| LegWaist | A5 | LegWaist-1 | -90 | 90 | 65 | ||

| LegWaist | A6 | LegWaist-2 | -145 | 1 | 65 | ||

| LegWaist | A7 | LegWaist-3 | -10 | 80 | 65 | ||

| LegWaist | A8 | LegWaist-4 | -30 | 30 | 65 | ||

| LegWaist | A9 | LegWaist-5 | -180 | 180 | 65 | ||

| LeftArm | A10 | LeftArm-0 | -180 | 120 | 210 | ||

| LeftArm | A11 | LeftArm-1 | -170 | 9 | 210 | ||

| LeftArm | A12 | LeftArm-2 | -175 | 175 | 240 | ||

| LeftArm | A13 | LeftArm-3 | -129 | 10 | 240 | ||

| LeftArm | A14 | LeftArm-4 | -175 | 175 | 300 | ||

| LeftArm | A15 | LeftArm-5 | -95 | 95 | 300 | ||

| LeftArm | A16 | LeftArm-6 | -90 | 90 | 300 | ||

| RightArm | A17 | RightArm-0 | -120 | 180 | 210 | ||

| RightArm | A18 | RightArm-1 | -170 | 9 | 210 | ||

| RightArm | A19 | RightArm-2 | -175 | 175 | 240 | ||

| RightArm | A20 | RightArm-3 | -10 | 129 | 240 | ||

| RightArm | A21 | RightArm-4 | -175 | 175 | 300 | ||

| RightArm | A22 | RightArm-5 | -95 | 95 | 300 | ||

| RightArm | A23 | RightArm-6 | -90 | 90 | 300 | ||

| Neck | A24 | Neck-0 | -65 | 65 | 114.6 | ||

| Neck | A25 | Neck-1 | -3 | 50 | 114.6 |

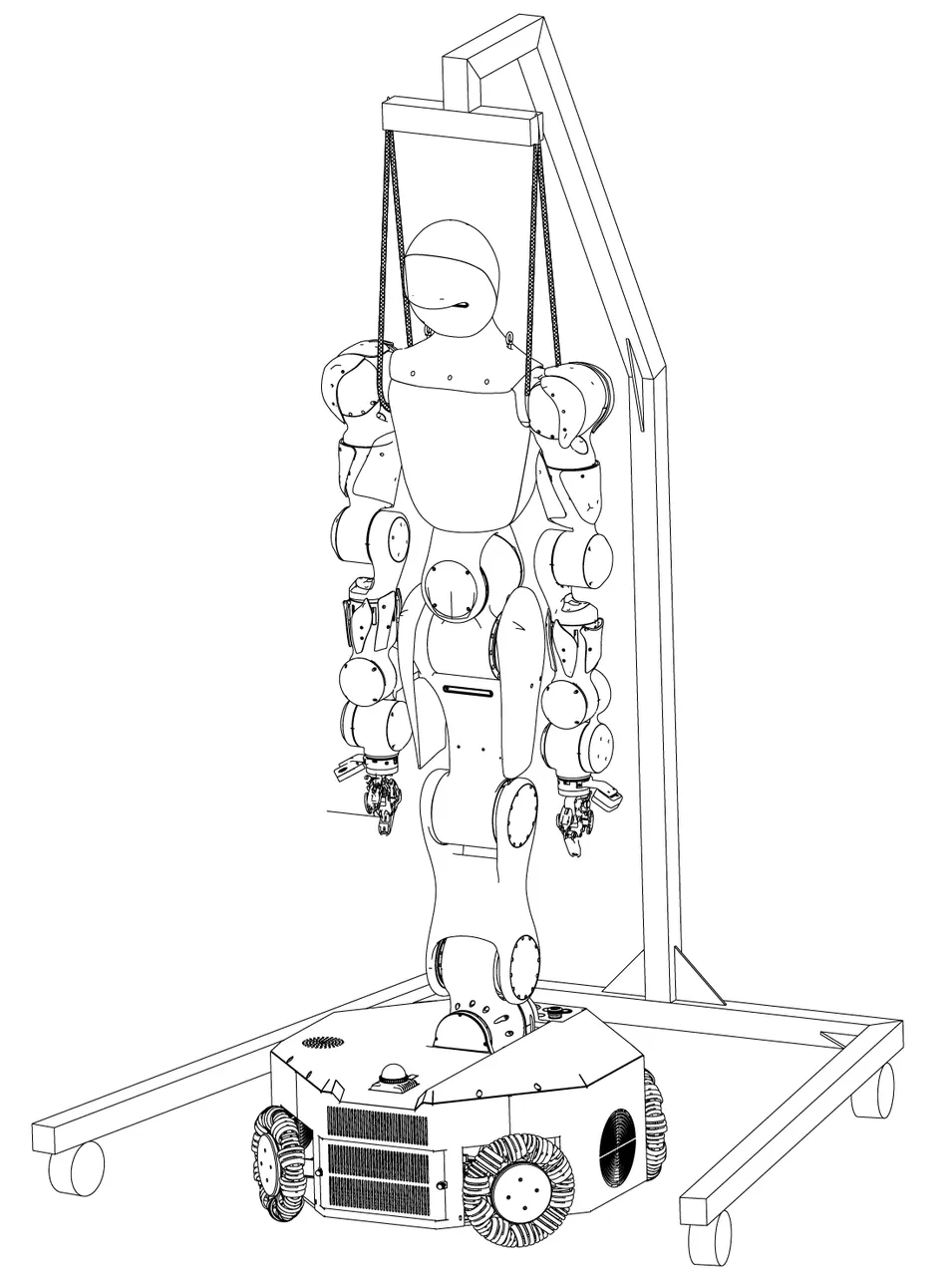

Hoisting Diagram

During robot maintenance or debugging, for the safety of the robot and users, it is recommended to use a hoist to protect the robot. The hoisting diagram is shown below:

Mobile Platform

Mobile Platform Overview

The mobile platform of this product is the core motion and control unit of the robot, integrating power drive, power management, AI inference, network communication, and safety control functional modules. The mobile platform supports standard charging, network communication, and emergency safety control, suitable for autonomous mobile operations in various industrial and service scenarios.

Power Supply

Charging Interface (LP20 Type 3-Pin Flange Female Socket) (Interface 15)

The charging interface of the robot body is located in the center of the right side of the mobile platform, adjacent to the bottom support plate, using an LP20 type 3-pin flange female socket form, requiring the Moz1 power cable with a dedicated plug for charging.

Usage Instructions:

- Please ensure that the charging cable matches the power adapter. Avoid using non-original accessories.

- The charging process is manual operation, requiring the operator to connect on-site and confirm the connection status.

- Connecting or disconnecting the charging cable while the robot is running is strictly prohibited to prevent accidental triggering.

Charging Parameter Specifications

| No. | Parameter | Notes |

|---|---|---|

| 1 | Charging Parameters | 54.8V / 10A (constant current constant voltage) |

| 2 | Charging Method | Manual connection (requires manual operation) |

| 3 | Cycle Count | ≥1000 times (regular battery health checks recommended) |

| 4 | Comprehensive Battery Life | ≥1000 complete charge-discharge cycles |

DANGER

Notes:

- Please confirm that the robot is in "stopped" state during charging, with no external interference.

- If any abnormality occurs during charging (such as overheating, odor), immediately disconnect power and contact technical support.